CRIS-TIM is launching an initiative meant to bring transparency in the cold cuts industry

Bucharest, June 20, 2018 – Cris-Tim family company is launching an initiative meant to bring transparency in the cold cuts industry and becomes the first brand that prints the meat percentage on more than 80 product packages.

To support this transparency claim, Cris-Tim is launching a campaign where it encourages consumers to make an informed choice and pick cold cuts with high meat content. And because extra meat means extra energy due to the higher protein intake, Cris-Tim campaign is dedicated to people who love meat and love living.

The initiative comes as a company commitment to respond to consumers’ desire to be correctly informed and to eat quality products. According to a 2017 ISA CENTRE survey, nearly 40% of the Romanian consumer mentioned the meat content as the most important factor when it comes to choosing a brand, while 47% of them mentioned quality.

Therefore, starting in June, more than 80 Cris-Tim products will have their packages marked on the front with the meat percentage or quantity they contain. For instance:

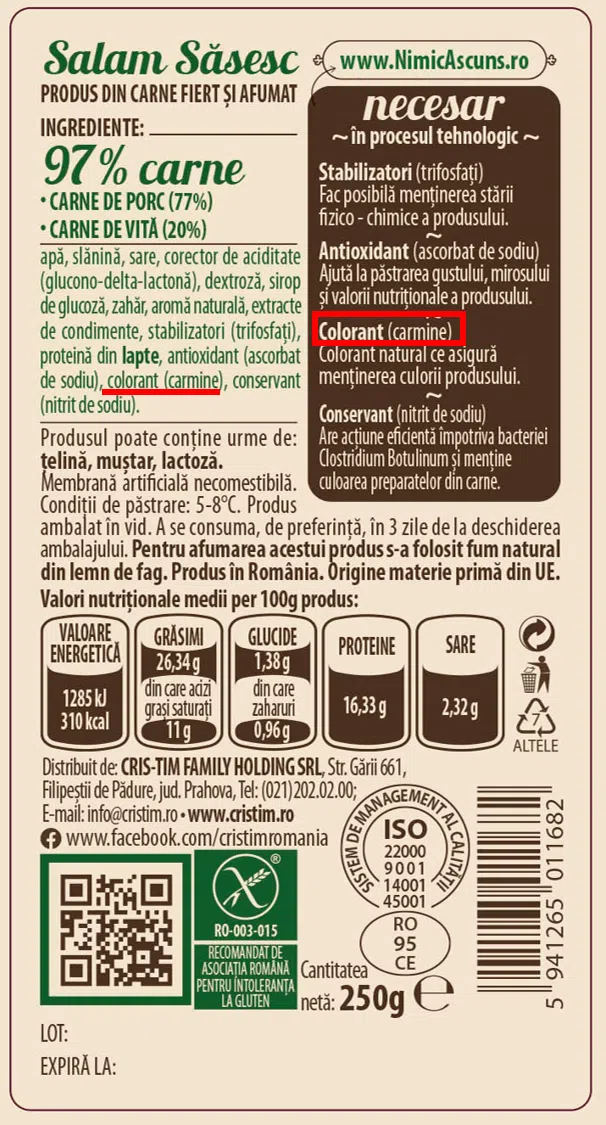

• Cris-Tim “Săsesc” Salami – 97% meat

• Bacon – 95% meat

• Pork Salami – 90% meat

• Cris-Tim Semi-Smoked Sausages – 95% meat

• Butcher’s Sausages or “Cabanos” Sausages – 90% meat

• Rustic Salami – 90% meat

• Summer Salami – 90% meat

• Cris-Tim Prague Ham – 80% meat

• Pork Pressed Ham – 80% meat

• Chicken Breast or Turkey Ham – 80% meat

• Gypsy Fillet, Azuga or Fillet – 80% meat

• Pork Country Style Salami – 80% meat

• Country Style Salami with Ham – 80% meat

• Cris-Tim Home Salami – 80% meat

• Cris-Tim “Bănățean” Salami -Tim – 127 gr meat at 100 gr of product

• Cris-Tim Sinaia Salami – 125 gr meat at 100 gr of product

• Pontic Salami – 128 gr meat at 100 gr of product

Apart from meat, Cris-Tim uses ingredients to ensure the taste and texture properties of the product, following well-known recipes and all applicable standards.

In our commitment to providing the highest quality products, Cris-Tim naturally assumes transparency when it comes to its products, both in the recipe by displaying the meat content, ingredients, and in the manufacturing process, the technology used and the production environment.

Moreover, the transparency initiative comes after the initiative to perfect Cris-Tim products and to revolutionise the meat product market that started in 2017 when the Clean Label was first launched. This innovation allowed Romanian people to enjoy cold cuts that are not only tasty but also gluten-free, starch-free, and free of soya, artificial flavours, added sodium monoglutamate and carrageenan.

Clean Label products are the result of more than 5 years of sustained efforts and investments in research and human resources, technology and recipes. Clean Label is a phrase that defines and represents an additive-free “clean product”. This result would have never been possible without the next-level technology of High Pressure Processing and the Ozone Technology which represent together the safety perfection of the product.

“We promise to bring to Romanians’ tables heathy and tasty products and to continuously invest in making them better.

Our first step in this direction was the Clean Label when we completely revolutionised the food industry (not just the cold cuts industry) and we have never stopped since. We work daily to provide the best products. We perfect our recipes and, even if we could have gone on a different path, we chose to produce them in the highest quality and safety standards.

It is a promise we made since the very beginning: to respect and value our customers as if they were family.

And to show our commitment to this cause, we launched this transparency initiative. We take pride of the fact that we manage to provide the best products and we are inviting everyone in the industry to the challenge of informing about the meat percentage”, states Radu Timiș, Cris-Tim President and Founder.

Cold cuts that have a high meat content have extra quality and taste, as well as a higher protein intake and extra energy, as meat is a major group in the nutritious pyramid.

On the shelves, consumers will find the label indicating the meat percentages on all products of Cris-Tim most beloved brands: Cris-Tim, Matache Macelaru’ and “Săsesc” Salami.

In 2017, Cris-Tim used more than 30,000 tone of meat during the manufacturing of its cold cuts. Last year, more than 140 million Cris-Tim products ended up on consumers’ tables.

The processed meat products market is continuously growing, and Romanians are increasingly choosing cold cuts. According to Nielsen data from the Retail Audit study, the processed meat category increased compared to 2017 and to last year, with 4% in volume and 12% in value. (Calculation based on Nielsen data from the retail audit service performed on the processed meat category on the Romanian market, sales volume and value for 2016 (DJ16->ON16) and 2017 (DJ17->ON17). (Copyright © 2017, The Nielsen Company.)

About Cris-Tim

With a more than 25 year history, Cris-Tim is the leader of the Romanian cold cuts markets, always providing its consumers with safe, fresh and healthy products, made using cutting-edge processing technologies, while applying food safety management systems (ISO 22000:2005) and environmental protection systems (ISO 14001: 2004).

Cris-Tim was awarded Trusted Brand prize in the meat product category for 7 years in a row, after the most important market survey, focused on the European consumer, and performed by Reader’s Digest Magazine across 15 countries, including Romania.

Consumers voted Cris-Tim “Săsesc” Salami as the Product of the Year 2018. Product of the Year is an international concept that rewards innovative products, and it is present in more than 40 countries. The study included all consumer products that presented an innovation during the last 18 months before the start of the competition, and the “Săsesc” Salami comfortably won in the “Salami” category.

Moreover, Cris-Tim is the most notorious cold cuts brand on the market, according to the lasted U&A study conducted with Mercury Research.