CLEAN LABEL

Our consumers are at the heart of all Cris-Tim Group decisions. To deliver the highest quality, Cris-Tim is committed to ensuring the transparency of the entire production process starting with the recipe, the display of the meat content, the listing of ingredients, the manufacturing process, the technologies used and the production environment.

Food safety is our foundation and the Clean Label, the High Pressure Processing Technology and the Ozone Equipment certify the care we take in every production step.

With our Clean Label, we deliver on our promise to offer products with the highest meat content, tasty and healthy, carefully prepared with the highest quality ingredients.

Our integrated business model allows us to verify all stages of the product, from production to distribution and delivery, and to guarantee the high quality of the final product that gets to our clients.

NOTHING HIDDEN. EVERYTHING AT SIGHT.

With total transparency regarding our ingredients, our manufacturing process and technology, we want to make sure that what you eat is tasty and healthy.

As part of this commitment, we launched the Clean Label, a major innovation in the food industry in Romania, which you can find on all Cris-Tim product packaging.

Gluten

STARCH

MDM

SOYBEAN

MONOSODIUM GLUTAMATE

ARTIFICIAL FLAVOURS

NO SECRETS

The Clean Label is our way of showing you that we are giving you the best we have. It is a guarantee that Cris-Tim products are tasty and healthy: gluten free, starch-free, free from MDM, soy, artificial flavours, added monosodium glutamate and carrageenan. To see that we have nothing to hide, let us show you the story behind our Cris-Tim products, from the ingredients we use and up to the moment you put them on your table.

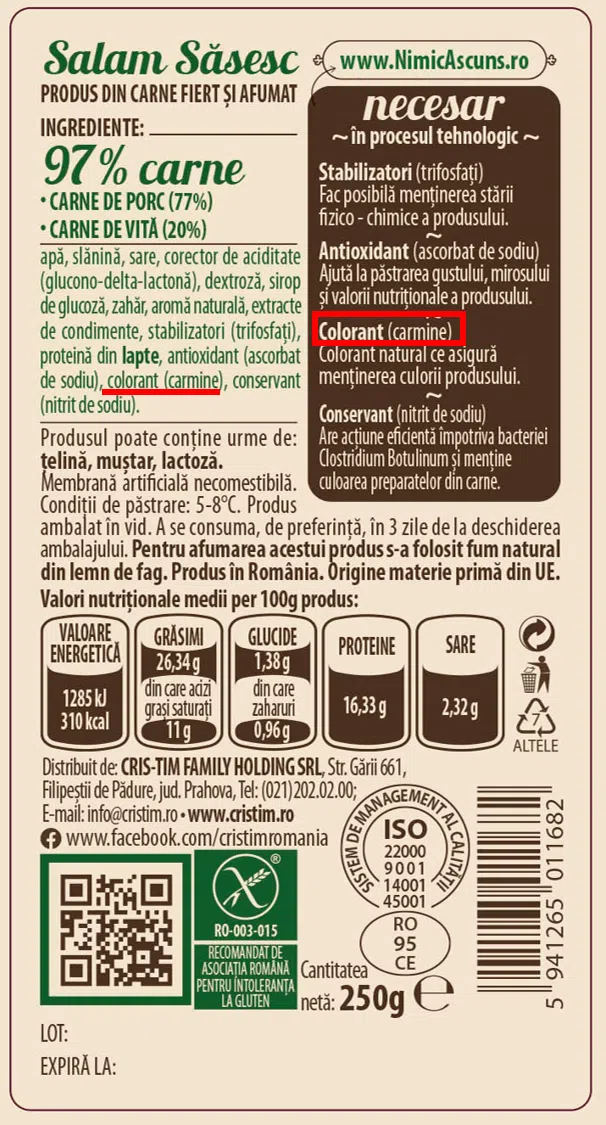

HOW DO YOU READ THE “CLEAN LABEL”?

With our Clean Label, we deliver on our promise to offer products with the highest meat content, tasty and healthy, carefully prepared with the highest quality ingredients. Discover what’s behind the Cris-Tim Label.

Ingredients needed in the technological process

STABILIZERS

ANTIOXIDANTS

COLOUR

PRESERVATIVES