Business Units

Cris-Tim Group core values are: the care for people, responsibility, innovation, tradition and quality. Our offering is comprised of a wide product range and business opportunities.

We are proud of the tight connection we have with our customers and we are committed to keep being at their side and at our partners’ side in order to build together the future we desire.

Our brands operate in four business units, all sharing a common mission – to connect our communities to unique gastronomic experiences, combining the taste with a balanced and healthy diet.

Cold Cuts

Market leader in Romania (volume and value)

Our brands: Cris-Tim, Obrăjori, Matache Macelaru’, Csárdás & Alpinia

RECUNOȘTINȚA PLANT

Our Recunoștința plant, in Filipeștii de Pădure, Prahova county is the core of our group. With a modern production unit of 60,000 square meters, it is in the most important investment in the area and one of the most modern cold cuts plants in Romanian.

Production Units:

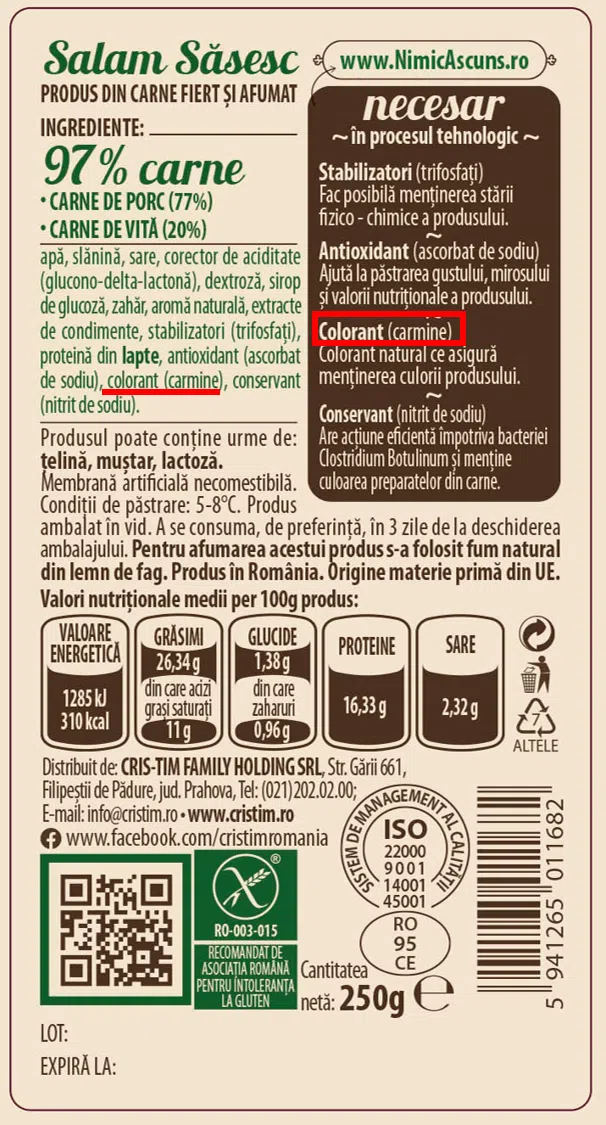

- Boiled-Smoked -in charge of producing all our boiled-smoked products, including Săsesc Salami.

- Raw-Dried – responsible of producing salamis, specialties and Sibiu PGI Salami

- Specialties – covering a wide range of cold cuts.

- Catering – in charge of producing the ready meal product range: grills and bechamel.

Modern Premises:

- Boning plant for the fresh meat used in production.

- Slicing chamber for all types of cold cuts.

- The warehouse with Warehouse Management System technology, implemented for a smooth delivery process.

- The largest private warehouse in Romania designed for raw materials with storage in freezing conditions.

- Natural gas freezing group for the production of technological steam and gas.

- Wastewater treatment plant.

- Modern physico-chemical and microbiological analysis lab.

- 3 MW solar panel system installed to reduce energy costs and environmental impact.

Măgureni Plant

Our second plant is located in Măgureni, a modern unit purchased in 2017. Măgureni plant has three production units: Boiled -Smoked, Raw-Dried and Specialties in a 6,000 square meter area.

Modern Premises:

- Warehouse with Warehouse Management System technology.

- Natural gas freezing group for the production of technological steam and gas.

- Wastewater treatment plant.

- 0.5 MW solar panel system installed to reduce energy costs and environmental impact.

Ready Meal

Ready Meal is our second most important business unit.

We opened up our first production centre in Bucharest in 2004, expanding it later in 2016.

The same year we opened a new plant in Filipeștii de Pădure, Prahova county.

Consumers can choose from a wide range of products: salads, grilled and cooked meals (prepared according to international and local recipes) as well as vegetarian meals.

Bucharest Plant:

- Here we produce salads and cooked meals:

- We are cooking as you do it at home and our products are not just pasteurised, but also fresh and tasty.

- The average daily output is 14 tons.

Filipeștii de Pădure Plant:

- Here we produce the grill and bechamel product range.

- We use automated equipment for grilling and cooking.

- Avem utilaje automatizate moderne pentru cântărirea și porționarea exactă a cantității de produse finite.

- The average daily output is 6 tons.

Dairy Products

ECOFERM is one of the most modern farms in Romania and it is comprised of a farm, a vegetable farm, an animal farm and a production plant. It is located in Boldești Scăeni, Prahova county, in a fertile and pollution free area.

Vegetable Farm:

- 100% of our cows’ nutrition comes from our vegetable farm. We plant wheat, barley, corn, alfalfa and triticale (grain) in our fields. The cultivated land is fertilized only with natural fertilizers. We produce about 16,000 tons of cereals in an area of over 1,300 hectares.

Animal Farm:

- We have 1,980 Holstein cows (recognized worldwide for the quality of their milk) that produce an average of 12,000 tons of milk per year.

- To give the most delicious milk not a day goes by without our cows going to their favourite SPA: modern stables with classical music, massage devices, showers, rest mattresses and automatic ventilation system.

- Each cow has its own digital passport that stores information about the date of birth, its family tree, lactations and births.

Production Plant:

- Raw milk processing unit, with a capacity of 60 tons/day.

- Unit of acidophilic dairy products, with a capacity of 30 tons/day

- Cheese department (cheeses, Kashkaval cheese and mozzarella), with a processing capacity of 30 tons/day.

Investments and Modernization Works:

- An automated production system has been implemented to increase the production to 60 tons/day.

- 0.5 MW solar panel system installed to reduce energy costs and environmental impact.